In the world of civil engineering and construction, fiberglass geogrids have become a game-changing innovation. Known for their exceptional strength, durability, and versatility,

fiberglass geogrids are transforming the way we approach soil reinforcement,

pavement stabilization, and structural support. Whether you're working on highways,

airports, or industrial facilities, fiberglass geogrids deliver unmatched performance

and reliability.

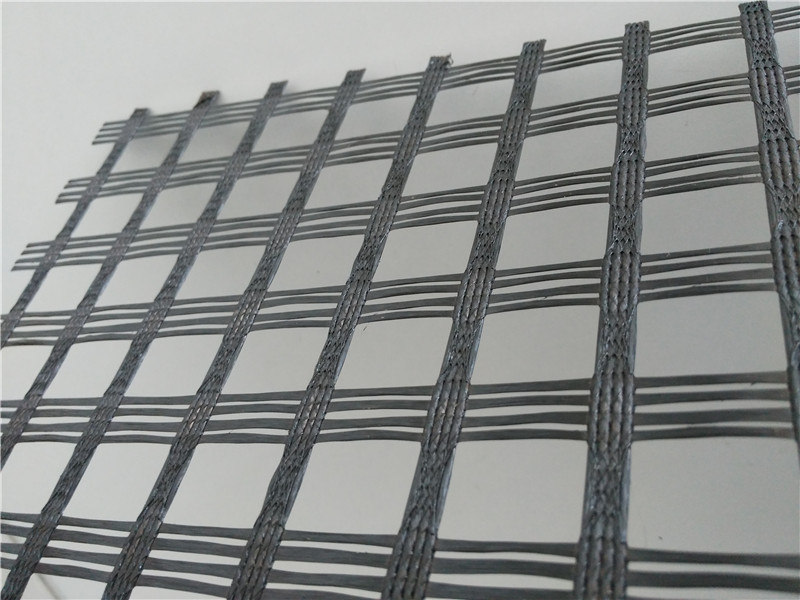

Fiberglass geogrids are grid-like structures made from high-strength fiberglass strands coated with a protective polymer layer. This unique combination provides superior tensile strength, resistance to environmental factors, and flexibility, making them ideal for a wide range of applications.

Here’s why fiberglass geogrids are the go-to choice for engineers and contractors:

✅ Exceptional Strength: High tensile strength ensures reliable reinforcement for heavy-duty applications.

✅ Durability: Resistant to UV radiation, chemicals, and extreme temperatures, ensuring long-term performance.

✅ Lightweight and Flexible: Easy to handle and install, saving time and labor costs.

✅ Cost-Effective: Reduces the need for thick layers of aggregate and minimizes maintenance costs.

✅ Eco-Friendly: Supports sustainable construction practices by reducing material usage and waste.

Fiberglass geogrids are used in a variety of applications, including:

Asphalt Overlays: Reduces reflective cracking and extends the life of asphalt pavements.

Concrete Pavements: Provides reinforcement for concrete slabs, preventing cracking and improving durability.

Subgrade Stabilization: Reinforces weak subgrade soils, improving load-bearing capacity and preventing settlement.

Base Reinforcement: Distributes loads evenly, reducing stress on the subgrade and extending the life of the road.

Reinforces runways and taxiways, ensuring stability and durability under heavy aircraft loads.

Provides reinforcement for heavy-duty floors and pavements in warehouses, ports, and manufacturing plants.

Stabilizes retaining walls and slopes, preventing erosion and landslides.

High Tensile Strength:

Fiberglass strands provide exceptional strength, making them ideal for heavy-duty applications.

Corrosion Resistance:

The polymer coating protects the fiberglass from environmental factors, ensuring long-term durability.

Customizable Solutions:

Available in various strengths, sizes, and configurations to meet specific project requirements.

Ease of Installation:

Lightweight and easy to handle, fiberglass geogrids can be installed quickly and efficiently.

A major highway project in Texas, USA, faced challenges with reflective cracking in asphalt overlays. The installation of fiberglass geogrids reduced cracking by 80%, extending the life of the pavement and significantly reducing maintenance costs.

Proven Performance: Trusted by engineers and contractors worldwide for reliable reinforcement.

Cost-Effectiveness: Reduces material and maintenance costs, offering long-term financial benefits.

Expert Support: Our team provides technical guidance and support, from product selection to installation.

Global Standards: Complies with international standards such as ASTM and ISO 9001, ensuring quality and reliability.

Ready to enhance your projects with the power of fiberglass geogrids? Contact us now to request a quote, learn more about our products, or speak with our experts. Let’s build a stronger, more sustainable future together.

Fiberglass Geogrids: Your Reinforcement. Your Stability. Your Success.

COMPANY:TAI'AN CITY RUIHENG BUILDING MATERIALS CO., LTD

Contact:Nickle Nie

Tel:008615866038408

Phone:008615866038408

Email:nickle@rhgeos.com

Add:NO.3566 LONGQUAN ROAD,TAI'AN HI-TECH ZONE,SHANDONG PROVINCE,CHINA