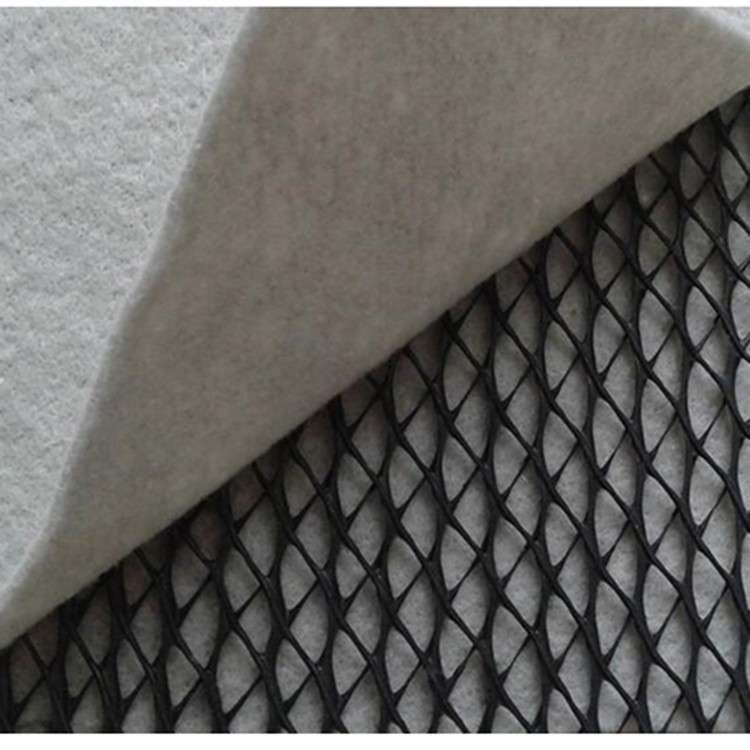

Composite drainage nets are advanced geosynthetic materials consisting of a three-dimensional polymer core bonded between layers of geotextile fabric. The polymer core provides high water flow capacity, while the geotextile layers act as filters, preventing soil particles from clogging the drainage channels. This innovative design makes them ideal for managing water in tunnel construction.

Composite drainage nets enhance tunnel performance through several key mechanisms:

Efficient Water Drainage:

The three-dimensional core ensures rapid removal of groundwater, reducing hydrostatic pressure and preventing water infiltration.

Filtration:

The geotextile layers prevent soil particles from entering the drainage system, maintaining long-term performance.

Structural Stability:

By reducing water pressure, composite drainage nets minimize stress on tunnel linings, enhancing overall stability.

Durability:

Resistant to chemicals, UV radiation, and extreme temperatures, ensuring reliable performance in harsh tunnel environments.

Superior Drainage: Rapidly removes groundwater, reducing the risk of water infiltration and structural damage.

Enhanced Stability: Minimizes stress on tunnel linings, extending the lifespan of the structure.

Cost-Effectiveness: Reduces the need for expensive maintenance and repairs, offering long-term financial benefits.

Ease of Installation: Lightweight and flexible, composite drainage nets can be installed quickly and efficiently.

Durability: Resistant to environmental factors, ensuring reliable performance over time.

Composite drainage nets are used in various aspects of tunnel construction, including:

Installed behind tunnel linings to efficiently drain groundwater and reduce hydrostatic pressure.

Placed at the base of tunnels to prevent water accumulation and protect the foundation.

Used along tunnel sidewalls to enhance stability and prevent water infiltration.

Installed at tunnel entrances to manage surface water and prevent it from entering the tunnel.

High Flow Capacity:

The three-dimensional core ensures rapid water removal, reducing the risk of waterlogging.

Filtration Stability:

The geotextile layers prevent soil particles from clogging the drainage channels, maintaining long-term performance.

Customizable Solutions:

Available in various thicknesses, sizes, and configurations to meet specific project requirements.

Eco-Friendly:

Supports sustainable construction practices by reducing material usage and waste.

A railway tunnel project in Switzerland faced challenges with groundwater infiltration, which threatened the stability of the tunnel lining. The installation of composite drainage nets behind the lining effectively drained the groundwater, reducing hydrostatic pressure by 90%. As a result, the tunnel has remained stable and dry for over a decade, with minimal maintenance required.

Proven Performance: Trusted by engineers and contractors worldwide for reliable water management.

Cost-Effectiveness: Reduces material and maintenance costs, offering long-term financial benefits.

Expert Support: Our team provides technical guidance and support, from product selection to installation.

Global Standards: Complies with international standards such as ASTM and ISO 9001, ensuring quality and reliability.

Ready to enhance your tunnel construction projects with the power of composite drainage nets? Contact us now to request a quote, learn more about our products, or speak with our experts. Let’s build a stronger, more sustainable future together.

Composite Drainage Nets for Tunnel Construction: Your Solution. Your Stability. Your Success.

COMPANY:TAI'AN CITY RUIHENG BUILDING MATERIALS CO., LTD

Contact:Nickle Nie

Tel:008615866038408

Phone:008615866038408

Email:nickle@rhgeos.com

Add:NO.3566 LONGQUAN ROAD,TAI'AN HI-TECH ZONE,SHANDONG PROVINCE,CHINA